Introduction

A thermistor is also a resistor whose resistance depends on temperature. A thermistor is a temperature-sensitive semiconductor component whose specific resistance changes rapidly with the changing of temperature. in another word, we can say that the resistance of the thermistor is changes when its temperature of its change. A thermistor is also called thermal resistance.

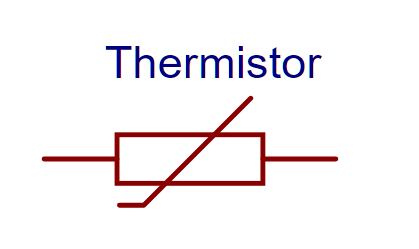

Symbol of thermistor

A thermistor is a passive component

Range

- The temperature range at this working is -550C to +1500C

- The value of resistance a thermistor may have between 0.5Ω to 107Ω

Types of thermistor

There are 2 types of thermistor

- NTC

- PTC

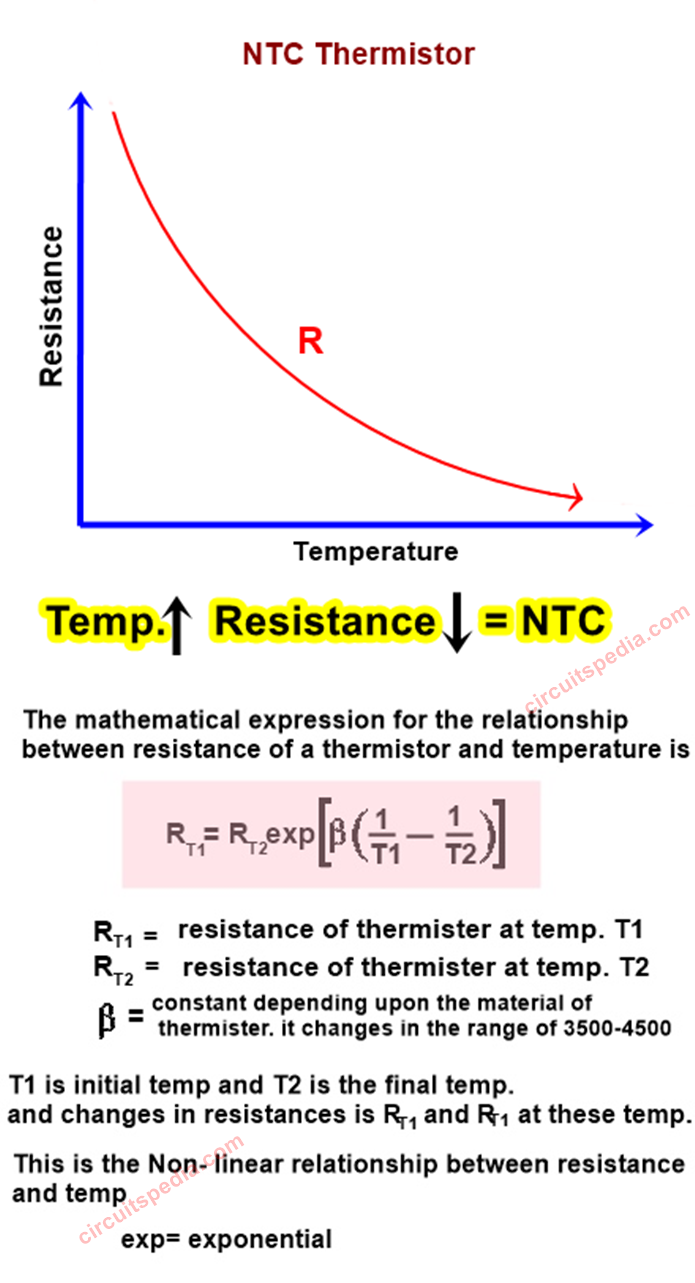

NTC- Negative temperature coefficient – In the NTC thermistor when the temperature increases the resistance decreases. The resistance of the NTC thermistor is inversely proportional to its temperature.

T ∝ R

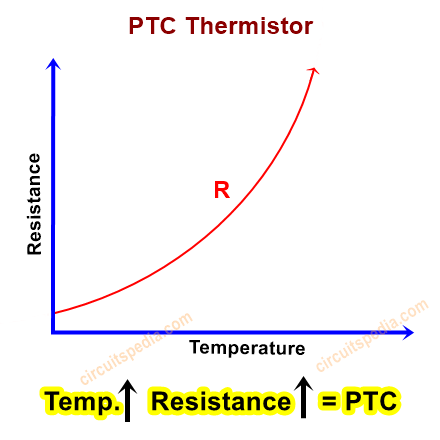

PTC- Positive temperature coefficient– in the PTC when the temperature increases the resistance also increases exponentially, and when temperature decreases resistance decreases.

T ∝ 1/R

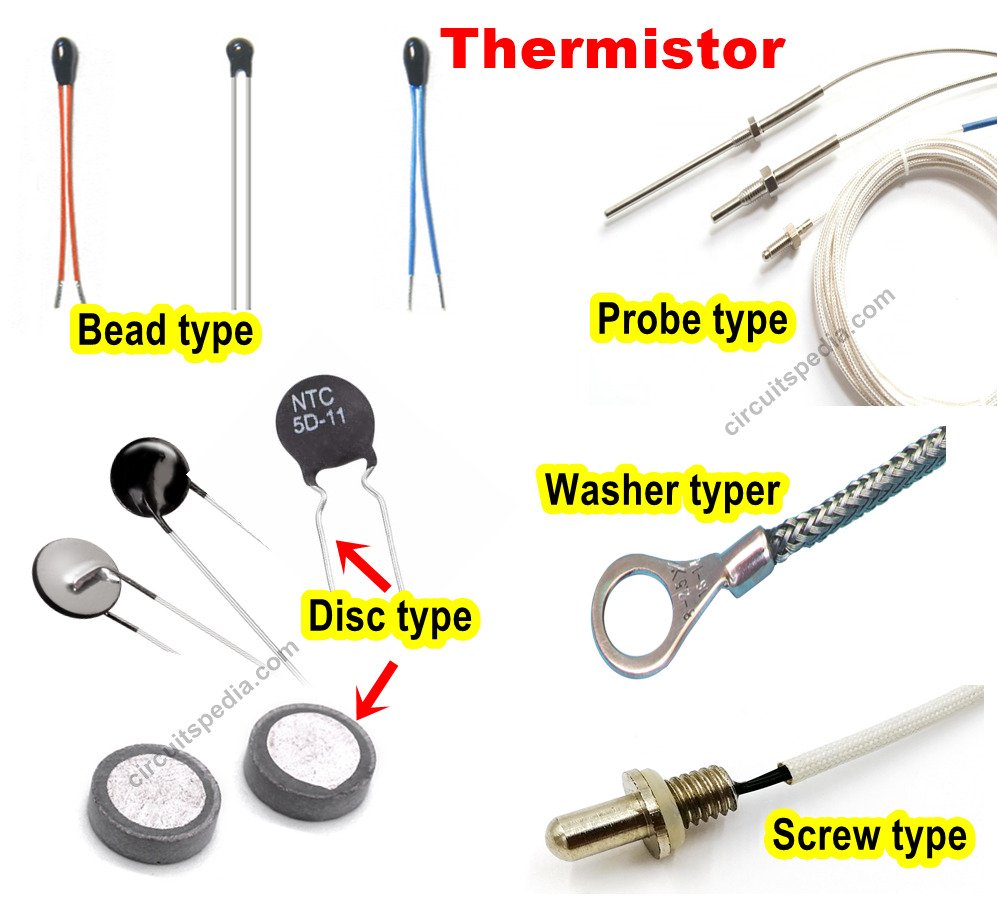

Thermistors are available in different sizes and shapes as per their value and use.

- Bead types

- Disk type

- Rod type

- Probe type

- Washer type

Bead type- smallest in size. The diameter of this type of thermistor is 0.015mm to 1.25mm

disk type– Made by processing material under high pressure into cylindrical shapes with diameters of 2.5mm to 25mm.

Probe type– The diameter of this thermistor is 2.5mm and its length varies from 6mm to 50mm.

Characteristics of thermistors

We will see the characteristics of thermistor only for NTC because of NTC thermistor is widely used

- resistance-temperature

- Voltage-current

- Current-time

Resistance-temperature characteristics

Voltage-current characteristics

The voltage is going to drop across the thermistor with the increasing the small value of current. As the current increases first the voltage increases, but after the peak value it starts decreasing with the current increasing. The reason behind this is the temperature of the thermistor is not start increasing at some current but after a certain value of current, the temperature of starts increasing in the thermistor and the resistance starts decreasing with the temperature increase. When the resistance decreases the value of voltage drop also decreases.

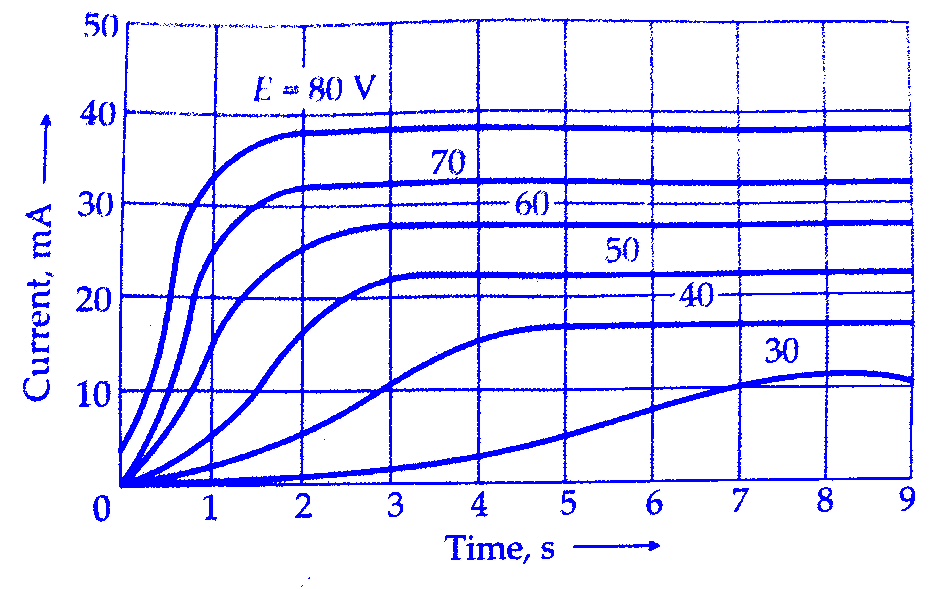

Current-time characteristics

Current-time characteristics

Current time characteristics show in the below graph. when we increase the applied voltage then the time delay also increases to reach the maximum current, and when decreasing the voltage level then the time delay to reach the maximum current is also decreasing, this happens because of the heating effect. At the low voltage, the thermistor produces low heat and at lower heat the resistance is high.

Advantages and disadvantage of thermistors

Advantages of Thermistors:

- Temperature Sensitivity: Thermistors exhibit a high degree of sensitivity to temperature changes, allowing for accurate and precise temperature measurements in a wide range of applications.

- Rapid Response: Thermistors have a fast response time, quickly registering temperature changes and providing real-time data.

- Small Size: Thermistors are compact in size, making them suitable for integration into small electronic devices and systems.

- Wide Temperature Range: Thermistors are available in various types, allowing for temperature measurements across a wide range, from extremely low to high temperatures.

- Cost-Effective: Thermistors are relatively inexpensive compared to other temperature sensors like thermocouples or resistance temperature detectors (RTDs), making them cost-effective for many applications.

- Simple Circuitry: Thermistors require straightforward circuitry for operation, making them easy to interface with microcontrollers and other electronic components.

- Stability: Thermistors offer good long-term stability, maintaining their calibration and performance over extended periods.

Disadvantages of Thermistors:

- Non-Linearity: The resistance-temperature relationship of thermistors is non-linear, meaning that the change in resistance is not proportional to the temperature change. This non-linearity requires additional calibration and compensation techniques for accurate temperature measurements.

- Limited Operating Range: While thermistors cover a wide temperature range, the specific operating range of a thermistor depends on its type. Some thermistors may have limitations at extremely high or low temperatures.

- Self-Heating Effect: Thermistors can generate heat when a current passes through them, which may cause a temperature measurement error or introduce interference in certain applications. Care must be taken to minimize the self-heating effect.

- Fragility: Thermistors are relatively delicate components and can be prone to damage if subjected to excessive mechanical stress or mishandling.

- Calibration Requirements: To achieve accurate temperature measurements, thermistors often require calibration to compensate for non-linearity and provide precise temperature data. This calibration process adds complexity and additional effort.

- Sensitivity to Environmental Factors: Thermistors can be sensitive to environmental factors like humidity, vibration, and pressure, which may affect their accuracy. Proper environmental protection and shielding may be necessary in some applications.

It’s important to note that the advantages and disadvantages of thermistors may vary depending on the specific type, application, and requirements. Careful consideration of these factors is essential when selecting and implementing thermistors in a given scenario

Applications of thermistors

A thermistor, short for “thermal resistor,” is a type of temperature sensor that exhibits a change in electrical resistance with temperature. Due to this characteristic, thermistors find numerous applications across various industries. Here are some common uses of thermistors:

- Temperature measurement: Thermistors are primarily used for temperature sensing in applications such as thermostats, HVAC systems, and industrial temperature control systems. They provide accurate and precise measurements over a wide temperature range.

- Temperature compensation: Thermistors can be used to compensate for temperature variations in electronic circuits. They are often incorporated into electronic devices to ensure stable operation by adjusting the circuit’s parameters with temperature changes.

- Thermal protection: Thermistors are utilized for thermal protection in electronic devices and systems. They can detect over-temperature conditions and trigger safety measures, such as shutting down the device or activating cooling mechanisms to prevent damage.

- Medical applications: In the medical field, thermistors are employed in various devices, including temperature probes, patient monitoring systems, and medical imaging equipment. They assist in accurately measuring body temperature and monitoring temperature changes during medical procedures.

- Automotive industry: Thermistors play a crucial role in automotive applications. They are used for temperature monitoring in engines, radiators, and HVAC systems. Thermistors help regulate engine temperature, prevent overheating, and control the climate inside the vehicle.

- Industrial processes: Many industrial processes require precise temperature control. Thermistors are used in industrial equipment like ovens, kilns, and chemical reactors to monitor and regulate temperature accurately, ensuring optimal process conditions.

- White goods: Thermistors are employed in household appliances like refrigerators, air conditioners, water heaters, and washing machines. They help maintain desired temperature levels and ensure efficient and safe operation.

- Weather monitoring: Thermistors are utilized in weather stations and meteorological instruments to measure temperature accurately. They help collect data for weather forecasts and climate studies.

- Food industry: Thermistors find applications in food processing and storage, ensuring proper temperature control in refrigeration systems, freezers, and food transport containers. They help maintain food safety and quality.

- Energy-efficient systems: Thermistors are integrated into energy-efficient systems, such as smart thermostats and energy management systems. They enable precise temperature control, reduce energy consumption, and enhance overall efficiency.

These are just a few examples of the many applications of thermistors. Their ability to measure and respond to temperature changes makes them versatile sensors in various industries and technological devices

- In household applications like microwave ovens, fridges etc.

- As circuit protection and current limiter

- Temperature sensors

- Self-regulating heating elements and self-regulating overcurrent protectors.

- It is used in vehicles to measure the temperature of coolant and oil.

- Used in a digital thermometer.

- For use to measure the conductivity of electrical components.

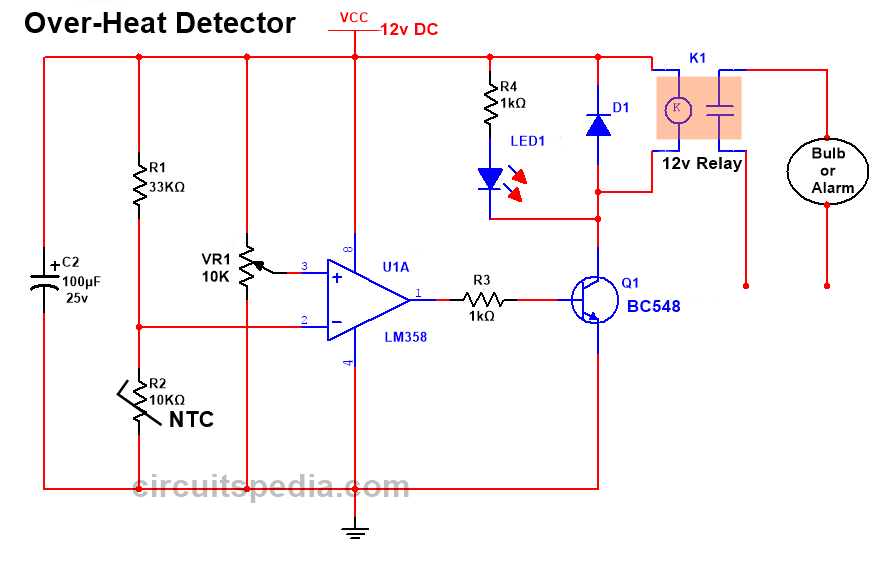

A simple circuit using an NTC thermistor is a heat sensor or overheat protection circuit

Also Read

- What is Optocoupler/optoisolator

- Active, Passive, Linear, Non-linear and Unilateral elements

- Relay working and types

- Dark sensor circuit using LDR and Photodiode

- What is zero cross detector

- Zener diode and its working