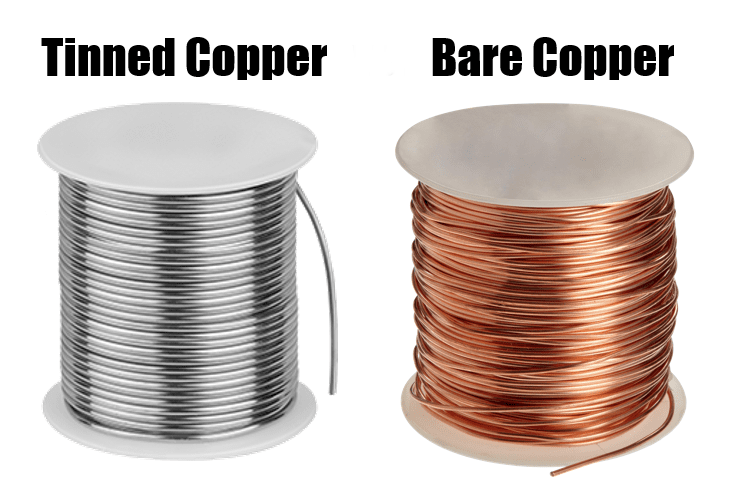

Tinned copper wire is a type of wire that has a thin coating of tin applied to its surface. This coating offers several advantages and is used in various applications for the following reasons:

Corrosion Resistance: Tin is highly resistant to corrosion, making tinned copper wire suitable for use in environments where moisture and other corrosive elements are present. The tin coating acts as a protective barrier, preventing the copper wire from oxidizing and deteriorating over time.

Solderability: Tinned copper wire has excellent solderability, which means it readily accepts solder when heated. The tin coating promotes good solder flow and adhesion, making it easier to create reliable and durable solder joints. This is particularly important in electrical and electronic applications where soldering connections are commonly used.

Improved Conductivity: While copper itself is an excellent conductor of electricity, the thin layer of tin on tinned copper wire can enhance its electrical conductivity. The tin coating helps to reduce the formation of surface oxides on the copper wire, ensuring better electrical performance and minimizing signal loss.

Easy Identification: The tin coating on tinned copper wire provides a distinct silver-gray appearance, making it easy to identify and distinguish from other types of wire. This can be helpful during installation, maintenance, and troubleshooting processes.

Aesthetics: In certain applications where the wire is visible or exposed, the shiny and uniform appearance of tinned copper wire can be aesthetically pleasing.

What are some specific applications where tinned copper wire is commonly used?

Tinned copper wire is commonly used in a wide range of applications across various industries. Here are some specific examples:

Electrical and Electronics: Tinned copper wire is extensively used in electrical and electronic equipment manufacturing. It is employed in the production of cables, wiring harnesses, connectors, and printed circuit boards (PCBs). The tinned surface facilitates soldering connections and helps prevent corrosion in humid or corrosive environments.

Automotive Industry: Tinned copper wire is utilized in the automotive industry for wiring harnesses, battery cables, and other electrical connections. The tin coating provides protection against moisture, chemicals, and vibration, ensuring reliable and long-lasting performance in challenging automotive environments.

Marine and Aerospace: Tinned copper wire is highly favored in marine and aerospace applications due to its corrosion resistance. It is used for wiring, grounding systems, communication equipment, and navigation systems on boats, ships, aircraft, and spacecraft.

Telecommunications: Tinned copper wire plays a crucial role in telecommunications infrastructure. It is utilized in the manufacturing of communication cables, coaxial cables, and network wiring. The tin coating enhances conductivity and protects against oxidation, ensuring reliable signal transmission.

Industrial Machinery: In industrial settings, tinned copper wire is used for electrical connections in machinery, control panels, and automation systems. It offers durability, reliability, and resistance to harsh industrial conditions.

Renewable Energy Systems: Tinned copper wire is commonly employed in renewable energy systems, including solar power and wind power installations. It is used for interconnecting solar panels, wind turbine wiring, and grounding systems. The corrosion resistance of tinned copper wire helps maintain the efficiency and longevity of these systems.

Medical Devices: Tinned copper wire finds applications in medical devices and equipment, such as diagnostic instruments, patient monitoring systems, and surgical equipment. The tin coating ensures reliable electrical connections and helps maintain the integrity of sensitive medical electronics.